Gates

All of the different style gates are available with VLF (very low friction) UHMW slide guides which guide the slide from top, bottom and side. Roller gates use ball bearing rollers or other styles of cam followers. The standard ball bearing rollers are on 3 1/2” centers under the inlet. When larger rollers are used, shed plates are welded to the channel frame and project toward the inside so they cover the outermost point of the rollers. This does reduce the effective area of the gate opening and should be taken into account when necessary.

The most common style operator is the Rack & Pinion with hand, cable or chain wheel operators. The R&P style operator can easily be converted to Electric Operated.

Gates that use a rack and pinion to control movement of the slide can be ordered with an electric drive to provide for remote operation. This is accomplished by a C-face motor, gear reducer and sprockets. A TEFC motor is standard with Class IIG as an option. Two Class IIG limit switches are standard and are set to indicate the fully open and fully closed position of the slide. Separate position indicators are optional for use on any manual, air, hydraulic or standard electrically-operated slide gate. The economical ‘VGC’ is a complete variable position controller for an electrically operated R&P slide gate.

Consult the factory for more information on these.

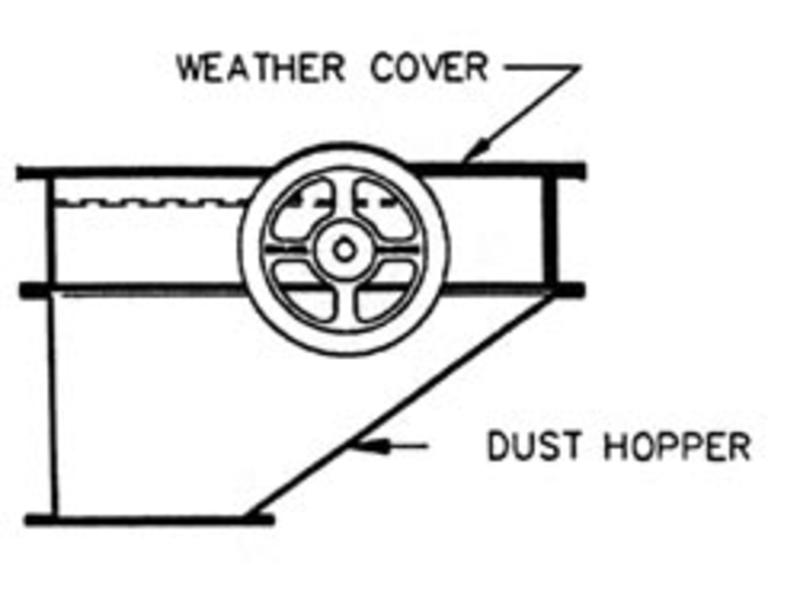

Weather/Dust Enclosures

All of the different style gates are available with a top and bottom weather/dust cover. A top-mounted cover is recommended when the gate is exposed to outside weather conditions. A full bottom dust hopper can be ordered to prevent dust build-up or leakage.

| Name | Type | Size |

|---|---|---|

Installation & Operation |

||

| Gate Installation | manual | 0 bytes |